In the field of environmental protection, AIM Magnet's permanent magnet also plays an important role. These magnets are used to separate valuable metals from waste, allowing resource recovery and reuse. AIM Magnet's permanent magnet greatly improves waste treatment efficiency with its high magnetic field strength and stability.

MSuper permanent magnets provide premium quality and high-performance magnetic solutions for industries around the world. Known for their impressive strength, stability, and efficiency, these magnets are ideal for applications in high-tech sectors, automotive systems, and manufacturing processes. MSuper’s permanent magnets are engineered for longevity, offering exceptional resistance to wear and tear while maintaining strong magnetic force. Companies looking to improve product functionality, streamline operations, and reduce maintenance costs rely on MSuper for durable, high-performance permanent magnets that meet their business needs.

In the area of industrial automation, there is a great role for AIM Magnet’s permanent magnet. Robots, automated production lines, and other types of industrial automation equipment require an exact and reliable motion control. This involves motor usage; the crucial part of which is a permanent magnet. With its high magnetic field strength and stability, AIM Magnet’s permanent magnet allows the motor to operate efficiently thus attaining precise motion control. A permanent-magnet motor utilizes the magnetic field generated by a current-carrying coil to interact with that produced by the permanent magnet leading to rotational torque. The torque generated has usefulness in different motors as well as actuators thus making it possible to achieve accurate motion control. Through precise control of material composition and production process, AIM Magnet ‘s permanent magnet attains high magnetic field strength and stability.

A substance that continuously produces a magnetic field is called a permanent magnet. The origin of this magnetic field lies in the magnetic moment inside the substance. They are highly recognized for their strong magnetic fields and stability. AIM Magnet specializes in manufacturing and selling permanent magnets. Basic principles behind Permanent Magnets revolve around electrons’ spin and orbital motion. In many materials, electron’s moments are not coordinated leading to cancellation between their magnetisms effects but in permanent magnets electrons moments are organized in one direction hence approaching a lasting magnetic field. By closely regulating the material composition and production process, AIM Magnet approaches high field strength and stability with its permanent magnetism. This is why they have wide applications such as electric vehicles, wind turbines, audio equipment etc

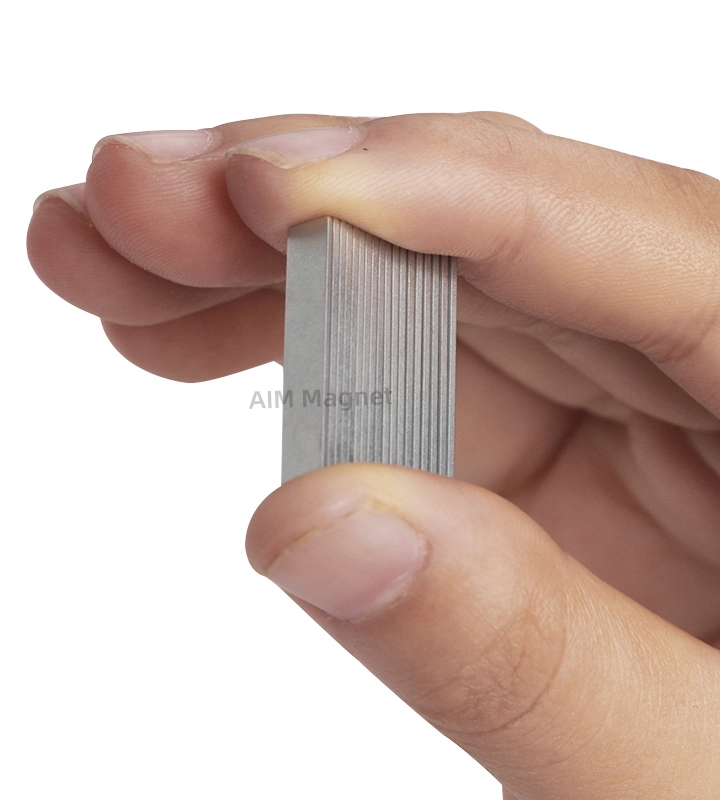

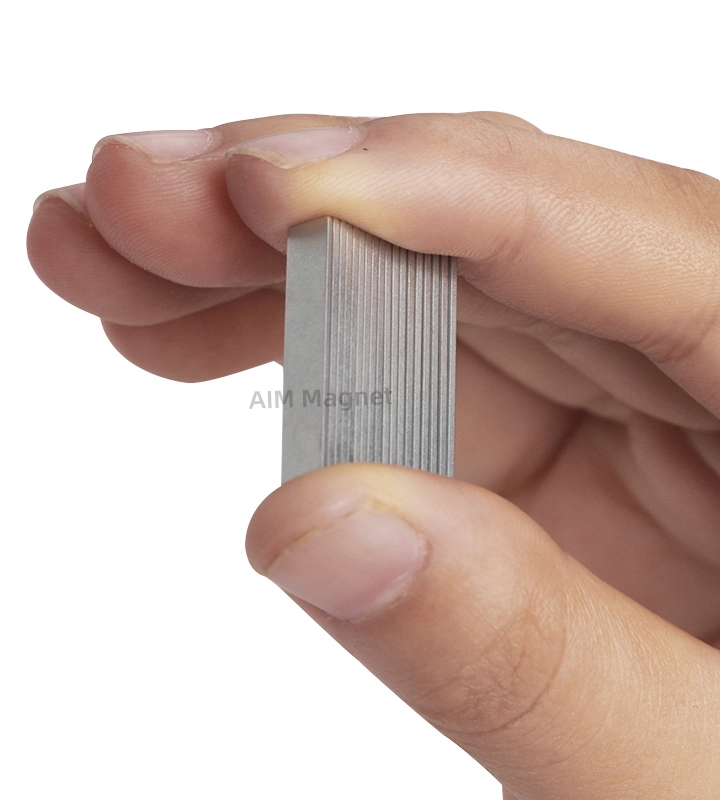

It is a precise and complex process making AIM Magnet's permanent magnet. The first thing that has to be done is selection of the right kind of magnetic material such as Neodymium-Iron-Boron (NdFeB) or Aluminum-Nickel-Cobalt (AlNiCo) among others. These materials are crashed into small particles which are then made to assume the desired shape using either high-temperature sintering or cold press forming technology. Lastly, these formed magnets must become permanently magnetic by aligning their internal magnetic moments in one direction to produce a continuous magnetic field. Strict quality management and accurately maintained manufacturing processes make AIM Magnet’s permanent magnets to have highly stable and strong magnetic fields. In addition, it also intends to develop new manufacturing technology and material for better performance of permanent magnets as well as reducing production cost.

Established in 2006 and headquartered in Shenzhen, China, AIM Magnet specializes in manufacturing permanent magnetic magnets and various magnet tools, including magnet hooks, MagSafe magnets, and more. Throughout our years of operation, we have been committed to delivering high-quality, innovative, and dependable products and services, with a focus on becoming a leading presence in the industry. Adapting to evolving market trends, we actively address the industry's ever-changing challenges. As a result, our company has continuously expanded its business scope into multiple fields.

We aim to establish ourselves as the foremost provider of permanent magnets on a global scale. By continually innovating, streamlining production processes, and delivering exceptional customer service, we are committed to attaining a leading position within the industry.

Innovate with high-quality permanent magnets, exceed customer expectations, and drive sustainable solutions for a positive impact. Striving for mutually beneficial customer relationships.

We manufacture a wide range of permanent magnets, including neodymium, ferrite, alnico, and samarium cobalt magnets.

Yes, we can manufacture permanent magnets in various shapes and sizes based on your specifications.

We pack our magnets in anti-magnetic and well-protected cartons, and we can ship globally.

Yes, we have a team of engineers who can assist with your design needs.

The MOQ depends on the size and shape of the magnet. Please contact us for more details.

We follow strict quality control procedures and each product is inspected before shipment.

Yes, we can provide an MSDS upon request.

Copyright © Copyright 2024 © Shenzhen AIM Magnet Electric Co., LTD - Privacy policy